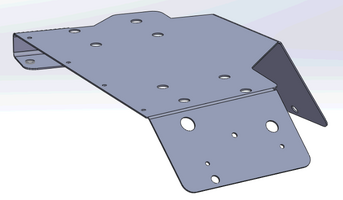

I probably could have gotten the ARB twin piston compressor to fit in the ABS tray, but I wasn't overly happy with the fit, and since my 2005 has all this room on the fender from moving the charcoal canister to the passenger rear fender, I figured I'd make a bracket to cleanly mount the compressor on my drivers side wheel well.

I'm still fine tuning it, and waiting for some parts to show up (3 pin wiring harness plug for the arb compressor, a different switch, and a different air chuck), but this is the basic concept I'm going with. I used 5mm bolts, which all fit through existing holes in the fender. I used some old valve stems that I cut up to use for rubber vibration isolators. I added some zip tie holes, and some holes for snapping in wiring harness clips I had to remove to make room. I didn't have to relocate anything else. I orginally made the first iteration from 18g mostly because it is cheaper, and I thought I'd be remaking it with thicker sheet metal, but honestly I don't think it needs it. I'm sticking with 18g for my final version.

I know many people like having the switch on their dash, and/or don't like having to open their hood to air up, but that wasn't my philosophy or goal. I like simple, so I wanted the switch and air chuck right next to the compressor. But nothing here prevents me from adding a manifold, or moving the switch or air chuck later on. I'm only using this for tire inflation. No air tools, no ARB lockers.

P.S. For those digging into the picture details, there's a couple of different versions of the bracket shown here, some with some minor flaws. When I get my delivery from brown santa, I'll pull the whole thing back apart, cut out a final version, paint, etc.

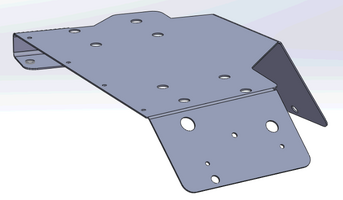

I'm still fine tuning it, and waiting for some parts to show up (3 pin wiring harness plug for the arb compressor, a different switch, and a different air chuck), but this is the basic concept I'm going with. I used 5mm bolts, which all fit through existing holes in the fender. I used some old valve stems that I cut up to use for rubber vibration isolators. I added some zip tie holes, and some holes for snapping in wiring harness clips I had to remove to make room. I didn't have to relocate anything else. I orginally made the first iteration from 18g mostly because it is cheaper, and I thought I'd be remaking it with thicker sheet metal, but honestly I don't think it needs it. I'm sticking with 18g for my final version.

I know many people like having the switch on their dash, and/or don't like having to open their hood to air up, but that wasn't my philosophy or goal. I like simple, so I wanted the switch and air chuck right next to the compressor. But nothing here prevents me from adding a manifold, or moving the switch or air chuck later on. I'm only using this for tire inflation. No air tools, no ARB lockers.

P.S. For those digging into the picture details, there's a couple of different versions of the bracket shown here, some with some minor flaws. When I get my delivery from brown santa, I'll pull the whole thing back apart, cut out a final version, paint, etc.